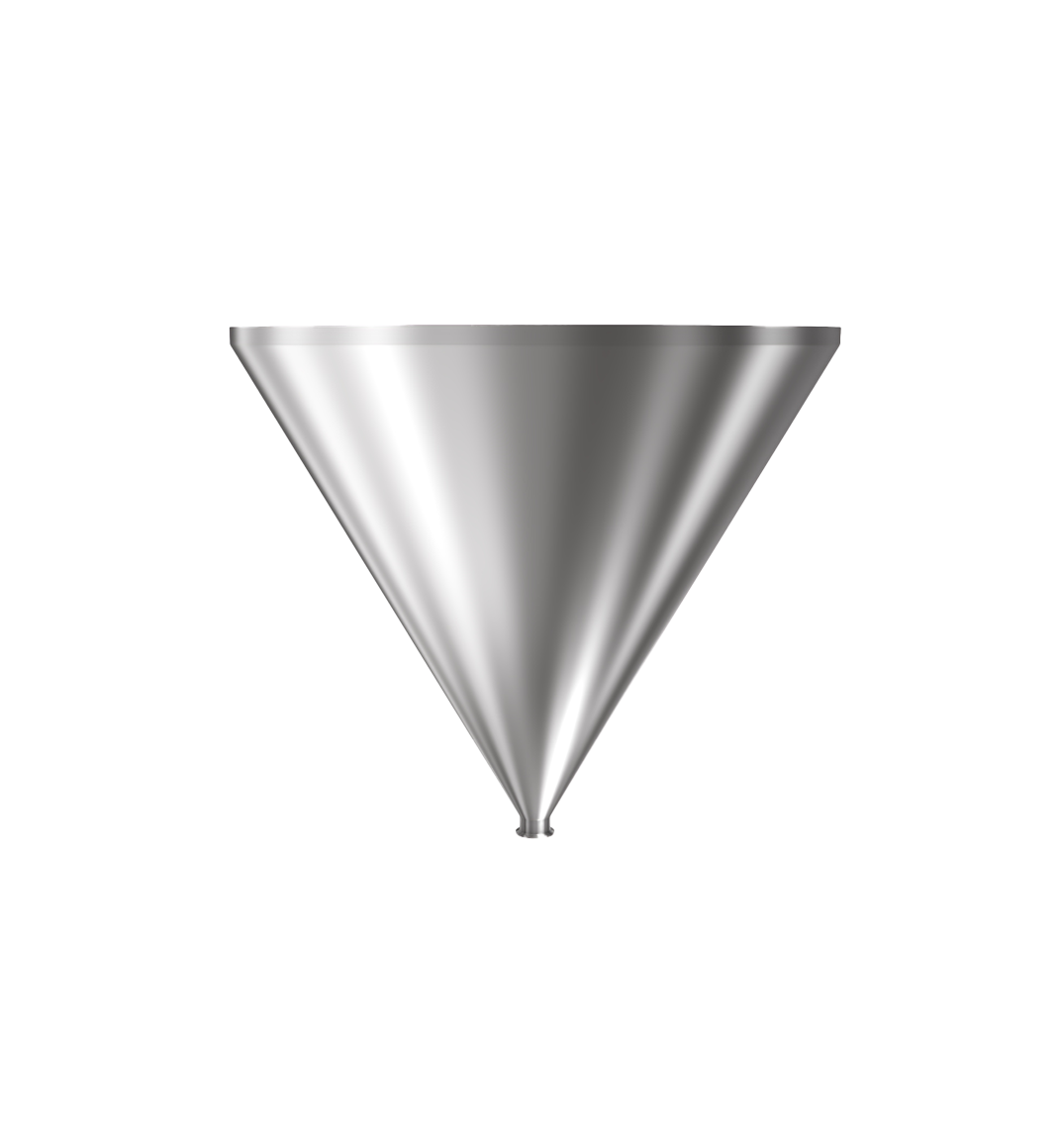

These hoppers are manufactured by joining a 100% seamless SS316 formed hopper and a SS316 machined 2″ sanitary tube end fitting. The weld has 100% penetration and is then ground smooth, thus eliminating common weld related issues such as corrosion, leaking, cracks, sanitary, and porosity issues. The smooth weld-free radius transition between the cone shaped bottom and cylinder shaped top improves both product flow and clean out for the applications requiring sanitary conditions. Sanitary hoppers have a 32ra inside finish, with a 125ra outside finish.

Our hopper funnels can be customized by us, or your fabrication shop of choice to be converted into various applications. Let TMS solve your sheet metal needs with our off-the-shelf or customized TMS hoppers. You can buy online, over the phone, or email with purchase order for customers with approved accounts. We stand behind our work with customer support based in Ohio.