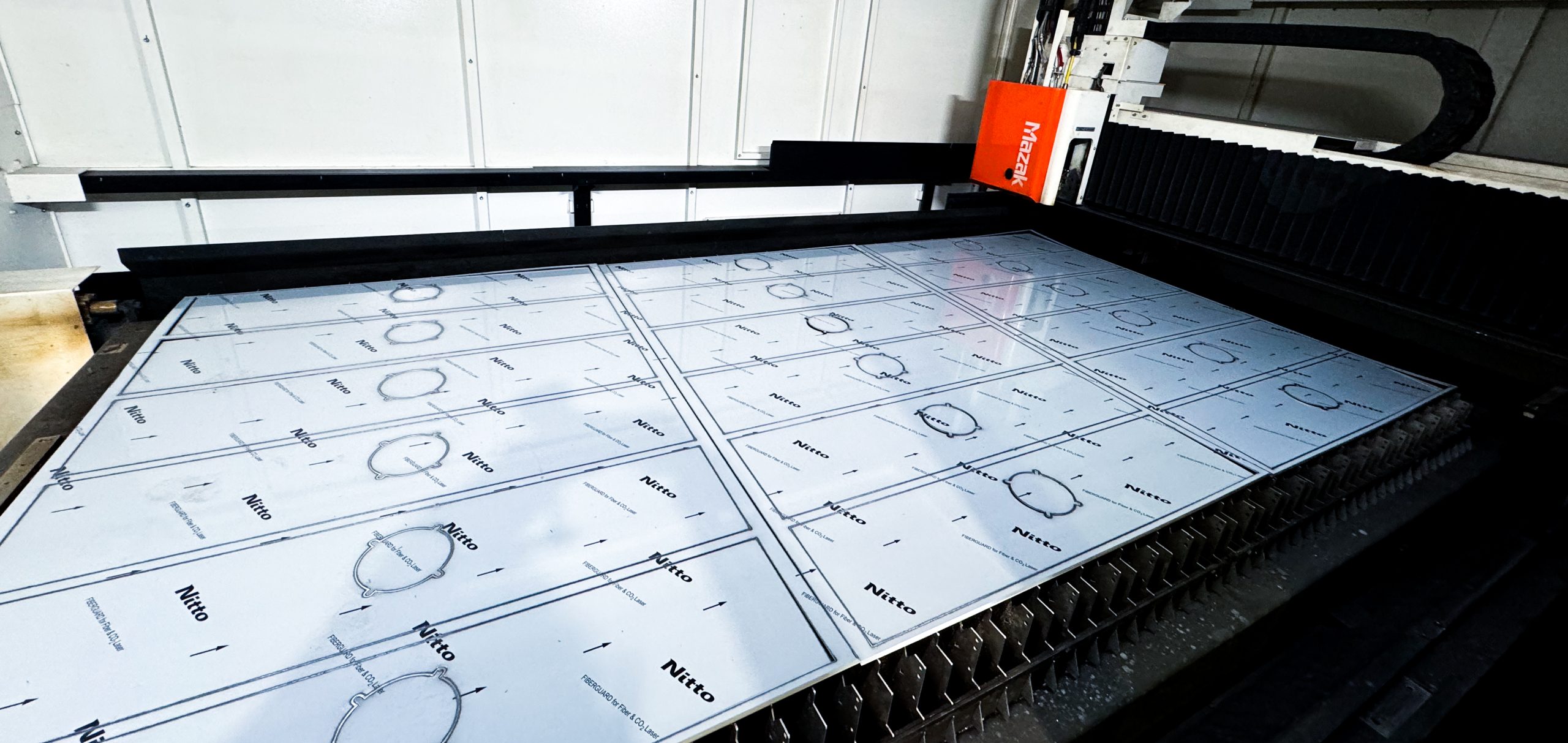

Secondary Metal Fabrication Process: Trimming

What is the Trimming Process and How is it Performed? Trimming is a process used to remove excess material to achieve a desired shape, size, and finish, while removing burrs and smooths out sharp edges. To trim a part, it is put on a lathe and processed by a highly skilled metal spinner, or a