The Difference of One-Piece Construction?

The Difference of One-Piece Construction

At Toledo Metal Spnning Company, we have been forming metals since 1929. With nearly a century of experience, we have mastered a wide range of processes including laser cutting, metal spinning, deep drawing, machining, rolling and seam welding, to build strong and durable high-performance parts. But what truly sets us apart us our ability to form complex parts as a single piece with minimal to no welds.

At Toledo Metal Spinning Company, we specialize in one-piece metal forming. Whether it’s for strength, cleanliness, or longevity, the difference is noticeable. One-piece constructions eliminate weld seams, reduce failure points and enhance overall strength.

A one-piece constructions can transform the outcome of a project. Forming a part from a single blank enhances the structural integrity, simplifies cleaning, and extends service life – especially in demanding environments like industrial food processing, oil and gas, or material handling, where performance and durability are non-negotiable. Seams and welds oftentimes become failure points and eliminating them can significantly reduce this risk in ways that matter on the job.

How so? Fewer seams mean stronger, more reliable components. In sanitary or food-grade applications, a single-piece construction streamlines the polishing process, making it more efficient and hygenic, as opposed to multi-piece welded assemblies. Not to mention this doesn’t require as much labor, and can help to reduce overall costs.

How do we accomplish this?

We utilize and combine our normal processes such as metal spinning, deep drawing, and rolling, alongside automated and manual welding, with nearly 100 years of experience in the industry. We have been forming metals since 1929, and are experts in these various processes. We know how each forming method works, and understand how and when to combine them to achieve the best possible results.

Benefits of one-piece constructions

- Fewer failure points

- Higher load-bearing strength

- Ideal for heavy-duty applications

- Increased longevity

- Smoother product flow

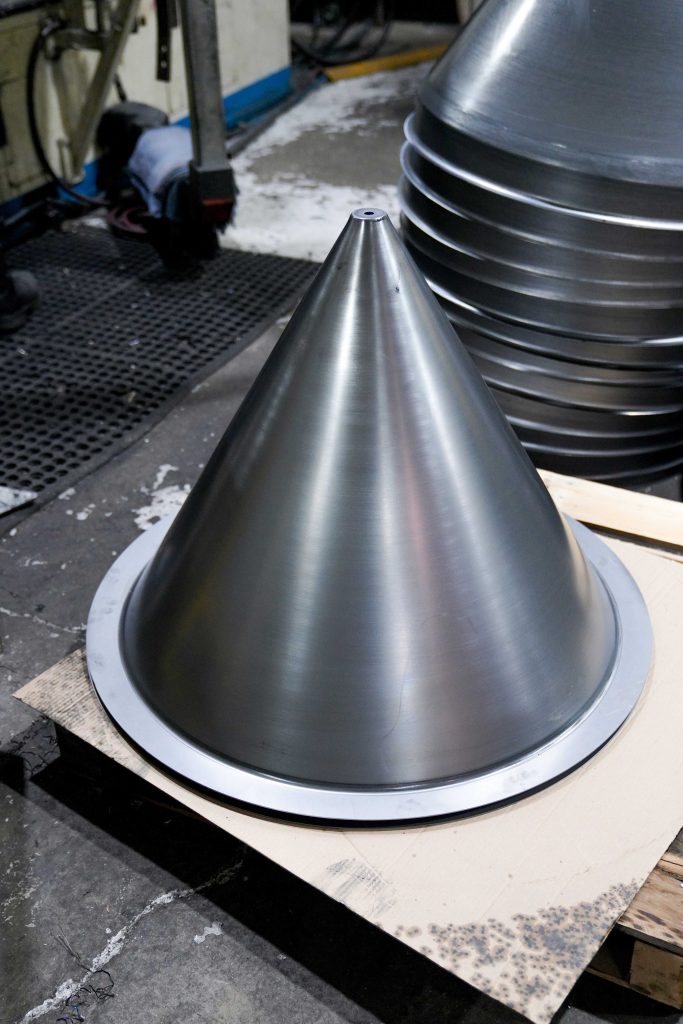

Standard and Custom Hoppers

Our hoppers are among our most recognized and trusted products, with a legacy that spans nearly a century. Designed as seamless, one-piece constructions, they offer exceptional durability and longevity—qualities that have made them a staple across industries. Each hopper can be customized to meet specific requirements, including fittings, side ports, cutouts, extensions, and sanitary or cosmetic finishes. Their weld-free construction not only enhances strength but also simplifies polishing, making them ideal for sanitary and food-grade applications where hygiene is critical.

Built to serve a wide range of industries—from heavy equipment and oil & gas to food processing, plastics, pharmaceuticals, and bulk material handling—our hoppers are engineered to handle everything from the lightest powders to the heaviest flows, consistently delivering performance that exceeds expectations.

Makes sense for majority of markets

In sanitary environments, the seamless interior is much easier to clean. One-piece constructions, especially our hoppers, are popular for equipment in food processing, pharmaceuticals, and sanitary environments. They are also ideal for heavier product flow because they are able to withstand much more weight and force, as opposed to pieces welded together. These pieces have the ability to withstand wear and corrosion, and when used with vibratory processes, they do not break down or ware.

Common Applications

- Hoppers

- Vessels

- Receptacles

- Covers

- Feeders

Why TMS is the right call

We have been doing this for nearly a century. At TMS, we specialize in a variety of processes, and we can be your one stop shop for anything involving laser cutting a blank, to forming a hopper, cup, pan, or dome, and adding customizations. Whether the project involves a need for strength, durability, longevity, cleanliness, or multiple pieces configured as one, we’ve got it covered. Whether it be used for industrial food processing, oil or gas industries, marine applications, or material handling, one-piece constructions help to reduce failure, enhance overall strength, and greatly increase longevity, while enhancing your overall process.