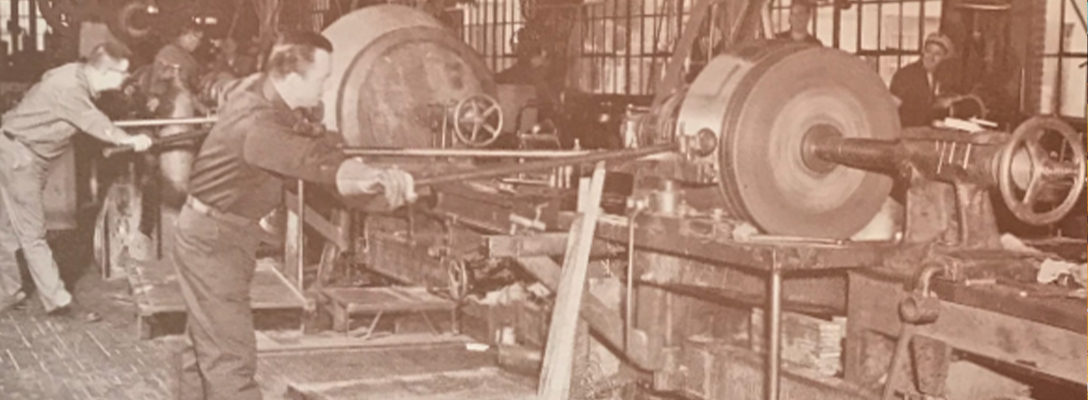

Metal Spinning has been deeply connected to our roots since our establishment in 1929. When we began forming metals, TMS was solely a metal spinning company. It wasn’t until shortly after our establishment when we started adding new processes to our wheelhouse, like deep drawing and stamping.

Metal spinning used to be solely done manually, and still can be. However, with new technology and innovation, Computer Numerical Controlled technology allows for metal spinning to be more of an automated process. This gives us the opportunity for more repeatability, and efficiency when producing large production runs.

Metal spinning can be a very complex process, and we have certainly mastered our craft. In short, the metal spinning, or spin forming process begins by moving a spinning roller over a laser-cut blank that rotates on a lathe. The bank is pressed against the tool by a tailstock. The blank is then rotated in a circular motion at a high RPM, where it is formed over the tool through a series of passes by the roller. The resulting piece is shaped as nearly a mirror image of the tool.

Want to learn more? Head to our Metal Spinning Resources for a deeper dive into the metal spinning process!

Curious about the history of metal spinning? Check it out here!

There are two general materials for metal spinning tooling: wood and steel. Each are utilized for different purposes. Depending on whether the part is being formed manually or with CNC technology will determine the type of material used for tooling. Click here for the full article…

At TMS, we have recently invested in milling capabilities, allowing us to manufacture our own spin tooling in-house! Take a look at the example below of our mill working on a wood tool used for trimming a spun part.

For more information on our milling capabilities, click here