The Importance of Craftsmanship in Marine Engineering and` Manufacturing

Marine and underwater environments come with the harshest of conditions, leaving no for error when engineering and fabricating oceanic and seafaring components. Through a variety of metal forming processes, creating durable and long-lasting parts is effortlessly achieved, ensuring each component meets the highest standards for quality, performance, and reliability

The Design and Engineering Phase

Build to Print marine component drawings may be sent to Toledo Metal Spinning to manufacture. Our engineers are fully equipped to assist with designing in-house tooling.

Our engineering department utilizes 3D parametric solid modeling CAD software for designing and MasterCAM to aid in the efficient precision tool design and fabrication processes. Our in house developed standard library of CNC tooling enables us to swiftly go from the tool design stage to the CNC fabrication build stage with minimum effort and time while maintaining precision. Most tools are designed and machined in our plant for speed, control, and economy.

With the capabilities of the laser, horizontal mill, hydroform press, and combination of other processes, intricate designs are effortless. When adding a corrosion-resistant metal such as stainless steel, aluminum, or titanium, custom-fabricated marine components are a perfect blend of durability, precision, and reliability.

- Marine-Grade Material Selection

- Stainless steel

- Galvanized Steel

- Carbon Steel

- Brass

- Aluminum

- Titanium

These marine-grade materials are ideal for marine or underwater environments because of the harsh environmental impacts they may face. Corrosion and constant exposure to salt water and other natural elements are two of the major impacts that will cause the wrong types of materials to deteriorate. It can be challenging to create a part that will withstand a multitude of factors, but with the correct combination of various metal forming processes, not only will its strength increase, it will be guaranteed a long-lasting life.

The Manufacturing Process: Bringing Marine Components to Life

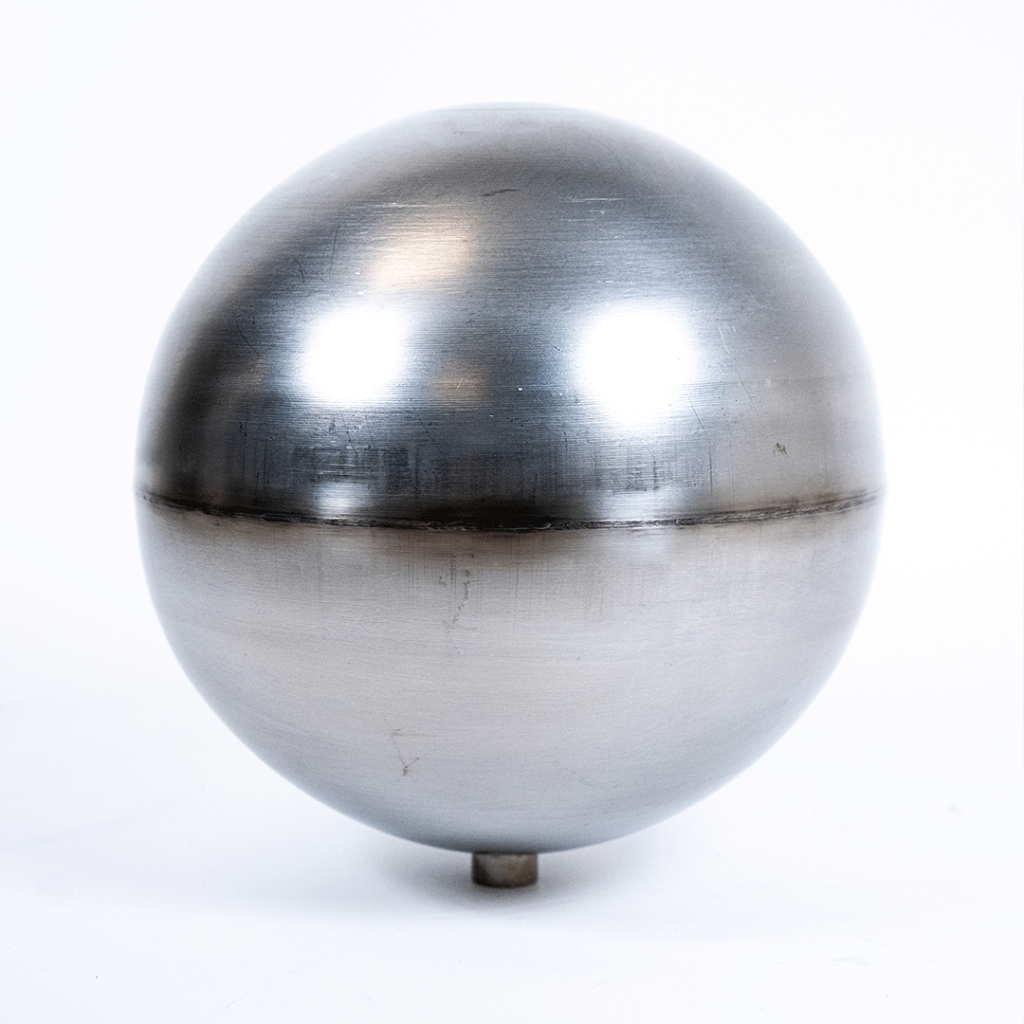

Metal spun stainless steel or aluminum hemispheres are typical marine applications. Utilized for various things such as tank heads, protective covers, oblongs, or structures on vessels.

Cutting-edge technology such as laser cutting, CNC turning or machining, and CNC metal spinning technology are all automated processes that yield the most precise and accurate parts, while increasing efficiency.

Examples of formed components essential to marine vessels:

- Propeller hubs

- Pump housings

- Ventilation components

- Navigation light housings

- Custom Interior Components

- Stainless Steel floating balls

- Float Shells / Oblong Ball Floats

- Aluminum Fish net floats

- Pressure vessel tank ends

- Plumbing and Pumps

- Pump Flanges

- Bilge Pump Components

- Flanged cylinders

- Protective caps or covers

- Subsea Enclosures/Housings

The manufacturing process includes choosing material, laser-cutting it into the correct size and shape blank, and its initial forming step, whether that be turning it into a preform or the final product. The part will then move from production, to washing, and then polishing, where if specified, will become shiny and aesthetically pleasing to look at. If a polish is not required, the product will be sent to shipping where it will be sent out to its next or final location.

Forming processes may include:

- Laser Cutting

- Machining

- Deep Drawing

- Hydroforming

- Metal Spinning

- Rolling

- Welding

Due to a variety of forming processes, various shapes and sizes may be formed, ensuring that each and every part is strong and built to last through any conditions, whether that be strong environmental effects of a harsh marine environment, or a calm day with sun beating down on the application.