The polishing process is a secondary metal fabrication process that is done to create a smooth and shiny surface by utilizing abrasives or chemical treatment, and can be done by hand or robotic automation. The purpose of adding a finish or polish is to improve the appearance by creating a nice, smooth, and shiny finish.

Adding a polish to a metal product improves its appearance by creating a smooth and shiny finish. Adding a finish also increases the part’s protection and durability by removing imperfections that show up on its surface, preventing corrosion and oxidation, and increasing its wear resistance. Polishing adds a protective later, enhancing the strength of the metal’s surface to be more resistant to scratches or wear and tear.

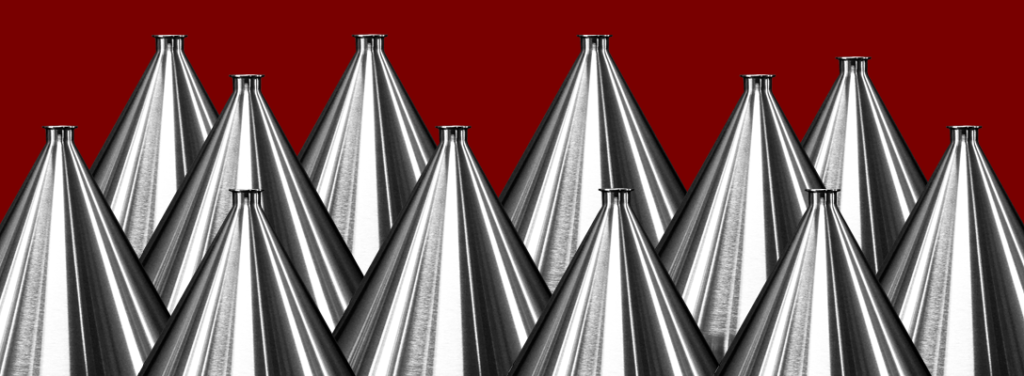

Polishes enable the part to be placed and utilized in sanitary and food-grade environments for markets like food processing, pharmaceutical, or medical device equipment. Sanitary-grade products such as hoppers and cones must have the correct polish applied, or they may accumulate bacteria or corrosion over time.

Another benefit is improving functionality and performance. Friction is reduced, which is beneficial in material handling, heavy industry equipment, or mechanical applications. The smooth, polished surface also enables easier cleaning and maintenance while preventing build-up.

Two popular processes for applying a smooth and shiny finish to metal products are manual and automated polishing.

Trained polishers apply various grades of abrasives to the part, achieving a polish pattern requested by the customer. Manual polishing is performed on a lathe which rotates the part at a high speed. The polisher uses a specified amount of abrasive to add the finish to the rotating part. This is a skill that requires in-depth training along with knowledge and understanding of a variety of abrasives, how they perform, and when they are needed. When the polishing process is complete, the correct abrasive pattern is recorded, and saved for future use.

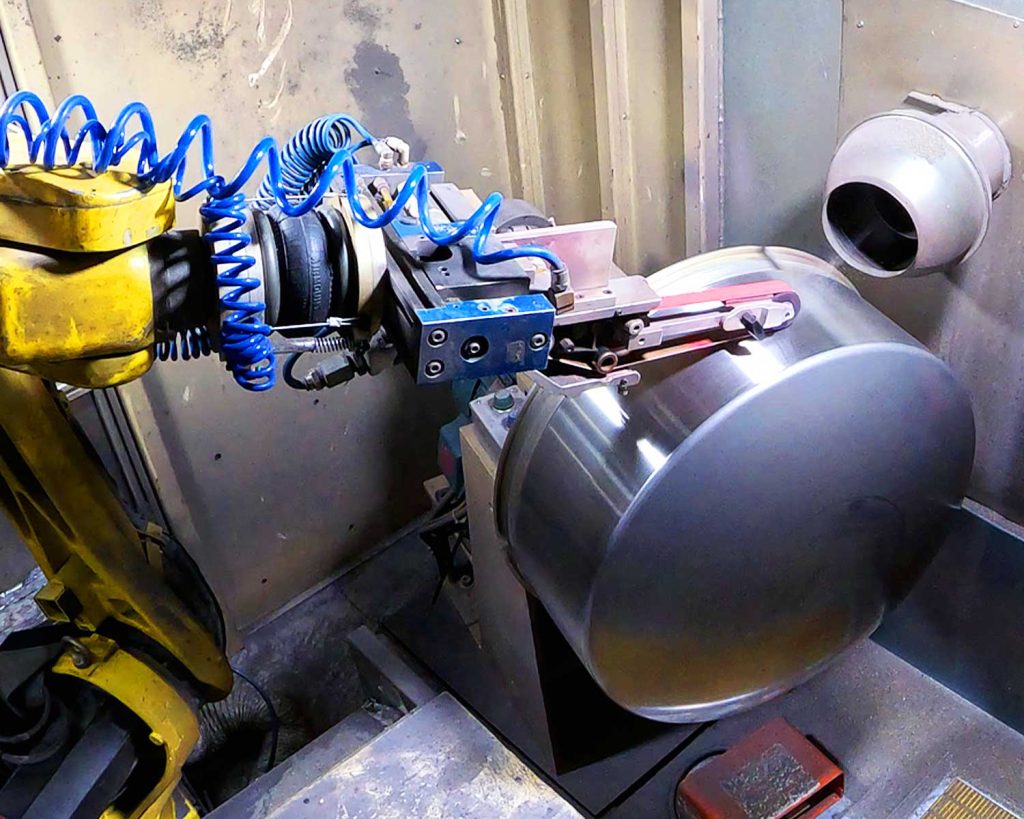

A robotic engineer will program the polishing robot to maneuver similar to the manual polisher. Robotic polishing can be extremely efficient with the ability to result in a beautiful finish. The robots utilize an abrasive belt the same way a manual polisher would with a tool in hand. The automated polishing process is also recorded and saved for future use. When the polishing process is complete, each part is inspected to ensure the highest quality result.